Howard Lovy's name came across my calendar (happy birthday!) and Josh Hall published a fresh post to "Where is my Flying Car?" – seems like a perfect time to post an everything-new-is-still-new-for-the-first-time-type update.

Published way back in 2017 in Molecular Systems Design & Engineering; reportedly one of the most-read Q3 2017 articles to boot. Also my first foray into arxiv territory for those limited in their journal access (arxiv.org/abs/1701.08202).

Tad Hogg*a Matthew S. Moses*b and Damian G. Allis*c

a. Institute for Molecular Manufacturing, Palo Alto, USA

b. Independent Consultant, Lafayette, USA

c. Department of Chemistry, Syracuse University, Syracuse, USA

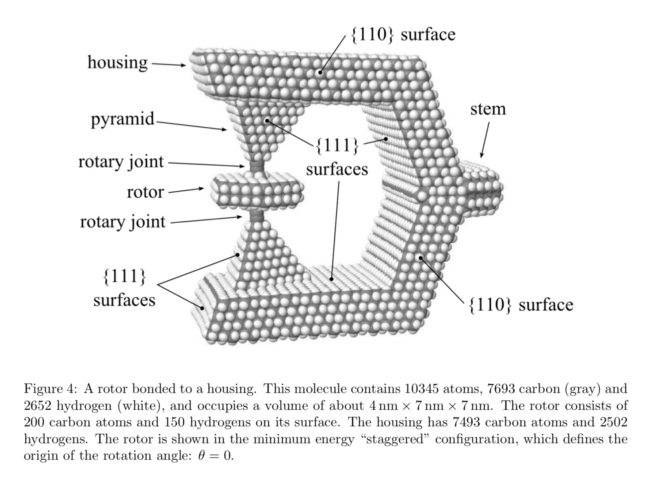

Abstract: A computationally-efficient method for evaluating friction in molecular rotary bearings is presented. This method estimates drag from fluctuations in molecular dynamics simulations via the fluctuation–dissipation theorem. This is effective even for simulation times short compared to a bearing's energy damping time and for rotation speeds comparable to or below typical thermal values. We apply this method to two molecular rotary bearings of similar size at 300 K: previously studied nested (9,9)/(14,14) double-walled carbon nanotubes and a hypothetical rotary joint consisting of single acetylenic bonds in a rigid diamondoid housing. The acetylenic joint has a rotational frictional drag coefficient of 2 × 10^-35 kg m2 s^-1. The friction for the nested nanotubes is 120 times larger, comparable to values reported by previous studies. This fluctuation-based method could evaluate dissipation in a variety of molecular systems with similarly rigid and symmetric bearings.

Mol. Syst. Des. Eng., 2017, 2, 235-252 (10.1039/C7ME00021A, direct link)